Pacific Power Solutions, one of the industry’s most in-demand solar, EV charger, and energy storage (BESS) Operations and Maintenance (O&M) providers, started its journey in 2018. With projects evolving into nationwide initiatives, the California-based company quickly outgrew manual processes, transitioning from Excel sheets to Scoop’s software solution in 2019 to meet escalating demand while maintaining a reputation for top-tier quality.

Specializing in industrial and commercial sectors, Pacific Power Solutions today, five short years later, manages upwards of 10 active monthly projects, including maintenance dispatching, and scaled their team from a small two-person operation to 30 field technicians.

Challenges

Pacific Power Solutions faced considerable challenges as they quickly started scaling. With rapid growth came added complexities. They quickly realized that, without a centralized system to manage their operations, current hurdles and limitations would hinder their ability to scale and maintain high levels of customer satisfaction.

- Disorganized Information Collection and Storage: The first challenge Pacific Power Solutions faced was the establishment of an accessible document repository. However, relying on online file storage services such as Google Drive limited their ability to create a standardized way to collect and complete information. They had no way of ensuring documents were adequately completed and associated with the correct job or client. Project pictures, forms, and checklists were not only incorrectly filled but also stored in unorganized and isolated folders across the organization without the necessary context for the back office teams, who would be left guessing as to their relevance.

- Time-Consuming and Manual Customer Communications: Since information was scattered, sifting through the wealth of information and files accumulated during site visits and projects became a cumbersome process. Consequently, customer communications were negatively affected as the team’s ability to retrieve and share essential information, files, and pictures was impaired. Countless hours were wasted going back and forth with customers via email to keep them updated on projects and dealing with document requests.

- Limited Project Visibility and Problem-Solving: Another significant limitation was visibility into project progress, handoffs and equipment used for their numerous ongoing projects. In addition, without real-time tracking and the absence of internal flagging mechanisms, management struggled to proactively solve potential issues.

Why Pacific Power Solutions Chose Scoop

Selecting Scoop as their solution was a decision grounded in practicality and configurability for Pacific Power Solutions. The company’s journey involved exploring various platforms. What ultimately set Scoop apart was its ease-of-use and robust customization capabilities, particularly in tailoring content based on client needs and essential data for effective asset tracking. The ability to efficiently adapt fields and reports to align with client expectations without the exorbitant consulting costs associated with most legacy business software became a pivotal factor in their decision-making process.

Results

According to Fletcher, the two most important drivers of success in his line of business are data management and reporting as well as having a well-equipped and competent team. This leads to better decision-making and higher customer satisfaction—precisely what they achieved with Scoop.

“The key to success is investing in the people that work for and with you—making sure they’re set up properly. This all trickles down to having the right solution to effectively execute projects and make data-driven decisions.”

– Fletcher Dyak, President of Operations

Effective Data Collection & Documentation

Creating a strong document repository starts with data collection and proper documentation completion. Scoop’s user-friendly interface and customization features allowed Pacific Power Solutions to seamlessly incorporate specific data collection and documentation requirements, enhancing the overall flow of information. The platform’s simplicity made it easy for technicians to input information, ensuring that required fields were completed before report submission for management review.

“Everything is now centralized and automatically stored—photo requirements for technicians can even be adapted depending on customer needs”

– Fletcher Dyak, President of Operations

In addition, with project sites housing 75 to 500 batteries in a storage system, keeping track of all equipment can be difficult. However, with Scoop’s barcode scanning feature, they’ve reduced human error to zero in serial number recording during the commissioning process. This eliminated miscalculations or inaccuracies by automatically and correctly storing serial numbers on the platform.

Keeping Everyone in the Loop

Scoop facilitates seamless external communication by granting customers direct access to their site documents and history directly on the platform. This client access not only saved time previously spent on emails and document requests but also enhanced transparency. The once daunting task of tracking information in a sea of documentation became effortless with Scoop, allowing Pacific Power Solutions to easily retrieve past site data, communicate effectively with clients, and eliminate the need for return trips.

“Many of our clients have given us accolades. With Scoop, they now have full access to their site history and documentation directly on the platform. This saves everyone time by providing them with the information they need when they need it, without our involvement.”

– Fletcher Dyak, President of Operations

Seamless Project Oversight

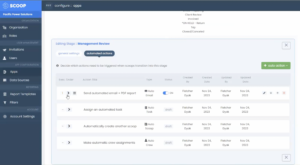

Scoop revolutionized project visibility and problem-solving for Pacific Power Solutions by offering customizable stages with full visibility for different stakeholders. The automated actions within Scoop streamlined the workflow—when a technician completed a report and marked it for management review, an automated email notified the dispatch team for a pre-client presentation review. This improved collaboration ensures thorough scrutiny before client submission.

Scoop also enabled swift identification and resolution of issues, allowing for immediate action if a problem persisted or if additional parts were required. The integration of Scoop essentially transformed the workflow, ensuring that project progress was not only visible in real time but also allowing for proactive and efficient problem-solving throughout the project lifecycle – often aided along with automated reminders and alerts for the appropriate team members.

Conclusion

As exemplified by Pacific Power Solution’s growth story, challenges faced by renewable O&M organizations are highly intertwined and interdependent. This can easily create a vicious circle, limiting opportunities for continued success. With the right solution, Pacific Power Solutions tackled many hurdles at once. Centralizing operations through Scoop had a domino effect, helping them improve document management, customer communications, and project visibility.

If you’re facing challenges similar to those of Pacific Power Solutions and want to improve your operations, reach out to one of our passionate experts today!