Nanocellulose infused with red onion extract shields solar cells from UV degradation

by Robert Schreiber

Berlin, Germany (SPX) Mar 20, 2025

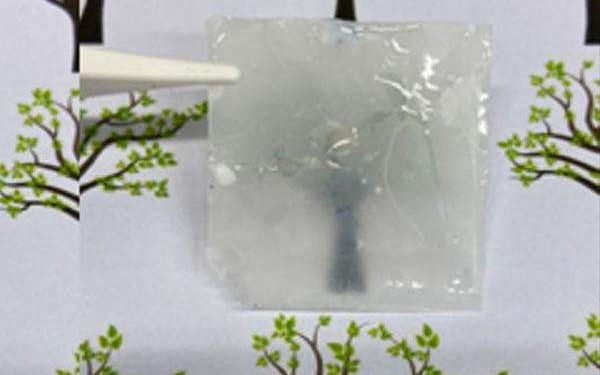

Researchers at the University of Turku in Finland have developed a bio-based film that provides high-performance UV protection for solar cells, utilizing nanocellulose treated with red onion skin extract. This marks the first comparative study of how various bio-derived UV filters perform over time.

Solar cells, susceptible to damage from ultraviolet radiation, are typically shielded by petroleum-derived films such as polyvinyl fluoride (PVF) or polyethylene terephthalate (PET). In an effort to reduce reliance on fossil fuels, researchers are exploring sustainable alternatives like nanocellulose, a material made by refining cellulose into nanoscale fibers that can be customized for UV blocking capabilities.

The study, conducted in collaboration with Aalto University in Finland and Wageningen University in the Netherlands, revealed that nanocellulose films dyed with red onion extract blocked 99.9% of UV rays up to 400 nanometres. This performance surpassed that of commercial PET-based filters, which served as a benchmark in the research.

“Nanocellulose films treated with red onion dye are a promising option in applications where the protective material should be bio-based,” stated Doctoral Researcher Rustem Nizamov from the University of Turku.

Researchers evaluated four types of nanocellulose films enhanced with red onion extract, lignin, or iron ions, all known for their UV-filtering properties. Among them, the film incorporating red onion extract demonstrated the most effective UV shielding.

Effective UV protection must be balanced with the ability to transmit visible and near-infrared light, essential for solar energy conversion. While materials like lignin excel in UV absorption, their dark hue hinders transparency. In contrast, the red onion-based film achieved over 80% light transmission at wavelengths between 650 and 1,100 nanometres, maintaining this level over extended testing.

To simulate prolonged outdoor use, the films were exposed to artificial light for 1,000 hours, equating to roughly one year of natural sunlight in central Europe. Researchers tracked changes in the films and solar cells through digital imaging.

“The study emphasised the importance of long-term testing for UV filters, as the UV protection and light transmittance of the other bio-based filters changed significantly over time. For example, the films treated with iron ions had good initial transmittance which reduced after aging,” tells Nizamov.

Tests focused on dye-sensitised solar cells, which are particularly prone to UV-induced deterioration. The findings also have broader implications for other solar technologies like perovskite and organic photovoltaics, where bio-based UV filters could play a crucial role.

“These results are also relevant for the UV protection of other types of solar cells, including perovskite and organic photovoltaics, as well as any application where the use of a bio-based UV filter is paramount,” Nizamov says.

Looking ahead, the researchers aim to create biodegradable solar cells that could serve as power sources in applications such as food packaging sensors.

“The forest industry is interested in developing new high-grade products. In the field of electronics, these may also be components for solar cells,” noted Kati Miettunen, Professor in Materials Engineering.

The University of Turku’s Solar Energy Materials and Systems (SEMS) group is exploring ways to integrate solar technologies into broader energy systems.

This work was part of the BioEST project, supported by the Research Council of Finland.

Related Links

University of Turku

All About Solar Energy at SolarDaily.com