Introduction

Hi everyone! With the growing popularity of green energy, solar panels have become a go-to choice for many homes and businesses. But while you’re enjoying the clean electricity generated by the sun, a hidden issue might be quietly impacting your energy yield and return on investment – “microcracks.”

During manufacturing, transportation, installation, or even daily operation, factors like mechanical stress, physical stress, sharp temperature fluctuations, or material incompatibilities can cause tiny cracks within these cells. Today, let’s take a deep dive into what solar panel microcracks are, and how advanced “anti-microcrack technology” is stepping up to protect your solar system, ensuring long-lasting, efficient power generation.

What are Solar Panel Microcracks? And Why Should You Care About

Thermal Stress?

Solar panel system look sturdy, but the solar cells (silicon wafers) inside are actually quite fragile. These micro cracks can emerge due to various stress factors such as mechanical and thermal influences during manufacturing and installation. Maintaining the integrity of the solar module during these phases is crucial for system performance. During manufacturing, transportation, installation, or even daily operation, factors like physical stress, sharp temperature fluctuations, or material incompatibilities can cause tiny cracks within these cells. Thermal stress during manufacturing can also contribute to the formation of microcracks.

These cracks are usually invisible to the naked eye, hence the name “microcracks.”

Don’t underestimate these hidden flaws; they are the “invisible killers” of solar panel performance:

- Reduced Energy Efficiency: Microcracks disrupt the smooth flow of electrical current. This can cause parts of the cell to become inactive (“dead zones”), leading to a decrease in the overall power output of the entire module.

- Shortened Lifespan: Over time, especially under thermal cycling (day/night temperature changes) and humid conditions, microcracks can grow. This can lead to “hot spots” (areas of high temperature) and even pose safety risks, ultimately shortening the panel’s effective lifespan.

- Increased Maintenance Costs: Performance degradation or outright failure means you might need to replace panels sooner than expected, increasing maintenance costs and creating uncertainty about your investment’s payback period.

Detection and Inspection Methods

Electroluminescence Crack Detection (ELCD) and Infrared Imaging

Detecting microcracks in solar panels is crucial for maintaining their efficiency and longevity. Two advanced methods that have proven highly effective are Electroluminescence Crack Detection (ELCD) and Infrared Imaging.

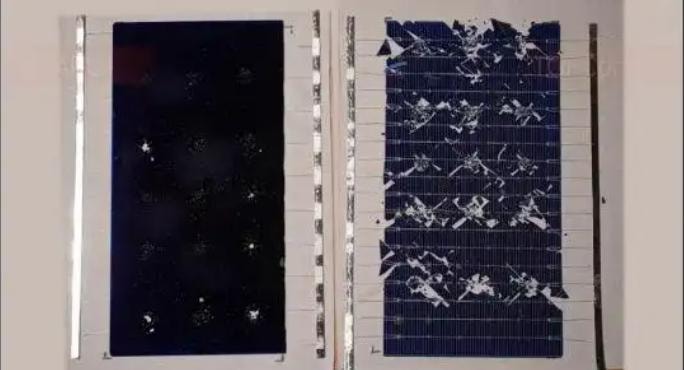

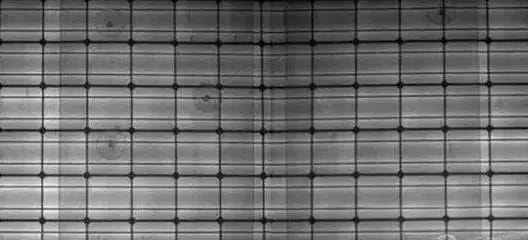

ELCD is a non-destructive testing method that uses electroluminescence to visualize and identify defects in solar cells. By applying a voltage to the solar panel, ELCD causes the cells to emit light, revealing microcracks, broken cells, and other internal defects that are invisible to the naked eye. This method is particularly valuable for quality control during manufacturing and for preventive maintenance in existing installations.

Infrared Imaging, on the other hand, captures the thermal radiation emitted by solar panels. This technique allows for the identification of temperature variations that indicate defects or irregularities. Hotspots, which are areas of elevated temperature caused by increased electrical resistance, can be easily detected using infrared imaging. These hotspots often signal the presence of microcracks or other issues that could compromise the panel’s performance.

Both ELCD and Infrared Imaging are widely used by solar panel manufacturers and system owners to ensure the optimal performance and longevity of their solar panels. By detecting hidden defects that other testing methods might miss, these technologies help maintain the efficiency and reliability of solar systems.

Anti-Microcrack Technology: Giving Solar Panels “Armor”

To combat the challenges posed by microcracks, the industry has developed several innovative anti-microcrack technologies, including glass-glass solar panels. These advancements focus on material selection and structural design to significantly boost a panel’s resilience:

- Dual-Glass Encapsulation (Glass-Glass Modules): Traditional solar panels typically have a “glass-backsheet” structure (glass on the front, polymer backsheet on the rear). Dual-glass modules, however, replace the plastic backsheet with another layer of glass.

This “sandwich” structure greatly enhances the module’s overall mechanical strength and structural stability. It’s much better at resisting external pressures and environmental stresses, effectively reducing the likelihood of microcracks forming. Think of it as giving the delicate cells a much stronger suit of armor. (Industry studies confirm this enhanced durability).

- Silver-Free Metallization: Manufacturing solar cells involves printing fine metal lines (busbars and fingers) to collect the generated current. Traditional methods often use silver paste that requires high-temperature sintering (firing). Silver-free metallization techniques employ different materials and application processes.

These methods avoid or minimize the thermal shock associated with high-temperature sintering on the silicon wafer, helping to preserve the integrity of the wafer’s crystal lattice. This reduces the risk of microcracks being introduced during the production process itself.

HJT solar panels utilize a unique complete half-cell processing technique that avoids cutting damage, thereby minimizing the potential for microcracks.

Anti-Microcrack Tech vs. Standard Panels: What are the Advantages?

Now that we understand the technology, what are the concrete benefits compared to standard solar panels?

- Higher Reliability: Panels with anti-microcrack technology are better equipped to withstand the physical stresses of manufacturing, shipping, installation, and harsh weather conditions (like hail, strong winds, and heavy snow loads), leading to lower failure rates. Mechanical stress can significantly impact solar panels during various phases such as transportation, installation, and external environmental conditions.

- More Stable Energy Production: With a reduced risk of microcracks, these panels typically experience a slower rate of power degradation over time. This ensures a more predictable and reliable energy yield throughout the system’s life.

- Longer Actual Lifespan: The enhanced structural integrity and lower risk of internal damage mean these panels can operate healthier for longer, often reaching or even exceeding their projected design life.

- Better Return on Investment (ROI): While the initial investment might sometimes be slightly higher, the increased reliability, stable energy output, and longer lifespan translate into a lower Levelized Cost of Energy (LCOE) and potentially a faster payback period for your solar investment.

A comprehensive approach to minimizing microcrack formation in solar panels involves understanding and mitigating mechanical stress during various stages.

Solar Panel Lifespan and Degradation

How Microcracks Affect Solar Panel Lifespan

Microcracks can significantly impact the lifespan and efficiency of solar panels. These tiny fractures increase electrical resistance within the solar cells, leading to elevated temperatures and the formation of hotspots. As a result, the overall power generation of the solar panel decreases, causing a decline in efficiency.

The typical lifespan of a solar panel is around 25 to 30 years, often referred to as its “useful life.” However, the presence of microcracks can accelerate the degradation process. According to a study by the National Renewable Energy Laboratory (NREL), solar panel output typically falls by 0.5% to 0.8% each year. Microcracks can exacerbate this degradation rate, potentially reducing the panel’s lifespan and efficiency even further.

In extreme cases, microcracks can lead to catastrophic failures, such as glass breakage or even fire. This underscores the importance of addressing microcracks to ensure the long-term performance and safety of solar panels. By investing in panels with advanced anti-microcrack technology, you can mitigate these risks and extend the lifespan of your solar energy system.

Why Does Anti-Microcrack Technology Matter More Today?

In the quest for ever-higher efficiency, modern solar technologies like large-format silicon wafers, multi-busbar (MBB) designs, and half-cut cells have become widespread. Detecting microcracks in solar panel installations is crucial for ensuring optimal performance and longevity. However, these advancements can sometimes make the cells more sensitive to stress and thus, potentially more susceptible to microcracks. Regular monitoring of solar panel surfaces is essential to identify visible cracks and enhance the reliability and longevity of solar energy systems.

This makes it even more crucial to pay attention to anti-microcrack features when choosing high-efficiency modules. The industry continues to research the mechanisms and impacts of different crack types (e.g., tree-like, complex, cracks parallel or perpendicular to busbars) to refine manufacturing processes and quality control, ensuring improved product quality.

Industry Trends and Future Developments

Emerging Trends in Solar Panel Manufacturing and Inspection

The solar industry is continuously evolving, with several emerging trends in solar panel manufacturing and inspection that aim to enhance efficiency and reliability. One notable trend is the use of advanced materials and technologies, such as HJT solar panels. These panels utilize an N-type monocrystalline silicon substrate known for its high purity and uniformity. This substrate provides additional elasticity and protection when the cell undergoes physical stress, thereby reducing the impact of microcracks on performance.

Automation and robotics are also becoming increasingly prevalent in solar panel manufacturing. These technologies help minimize the risk of microcrack formation during the production process by ensuring precise and consistent handling of materials. Additionally, there is a growing focus on sustainability and environmental responsibility within the industry. Companies are exploring new ways to reduce waste and improve recycling processes, contributing to a more sustainable future.

In terms of inspection methods, advanced technologies like ELCD and Infrared Imaging are gaining traction. These methods offer a more accurate assessment of solar panel quality by detecting hidden defects that other testing methods might miss. As the solar industry continues to innovate, we can expect to see new and exciting developments in both manufacturing and inspection techniques, further enhancing the reliability and efficiency of solar panels.

Conclusion: Make a Wise Choice, LINKSOLAR Customizes Your Reliable Future with Leading Solar Panel Manufacturers

Hidden cracks are a key factor affecting the long-term performance and reliability of solar panels. Fortunately, with the continuous development and application of anti-hidden crack technologies such as double-glass components and silver-free metallization, we now have better options to resist this “invisible killer”.

When you choose a solar system for your home or business, in addition to paying attention to peak power and efficiency, be sure to take the anti-hidden crack performance of the components into consideration. Choosing solar panels with advanced anti-hidden crack technology is an important guarantee for your long-term stable power generation income and safe and reliable operation of the system. It is a wise investment with an eye on the future.