Solar testing organizations are getting more serious about testing solar panels’ resilience against hail damage.

VDE Americas and RETC, part of the VDE Group, today introduce the hail resiliency curve (HRC) test that simulates real-world hailstorm conditions where solar panels may face numerous impacts from a range of hailstone sizes and wind speeds during server storms. The HRC test involves firing a series of small to large hailstones at low to high speeds at solar panels representing specific models and brands until glass fracture occurs, which gives solar developers, owners and operators accurate data for a panel’s “breaking point.”

“Conventional hail risk models that are relied upon by many in the insurance community are severely antiquated and outdated,” said Brian Grenko, president and CEO of VDE Americas. “Hail resiliency curve test results provide a superior characterization of solar panel hail resiliency, reducing uncertainty for investors and insurance providers.”

The new HRC protocol will allow solar panel manufacturers to optimize hail-hardened product designs and demonstrate their performance advantages relative to conventional products; project developers to perform cost-benefit analyses of different solar panels and tracker tilt angle combinations to mitigate hail damage risk; and insurance providers to appropriately right-size hail damage coverage and premiums based on empirical data rather than speculation.

“The solar industry has long needed a more rigorous approach to hail testing,” said Cherif Kedir, president and CEO of RETC. “The HRC test fills this knowledge gap by providing our customers with actionable data on solar panel hail resilience across the complete impact energy spectrum of real-world hailstorms. Moreover, the rigorous sample size ensures a more thoroughly vetted solar panel characterization.”

Glass, solar and other industry experts and stakeholders collaborated on the development of the test. Mike Pilliod, president and chief technical officer at materials engineering firm Central Tension, assisted by providing advice on glass performance.

“What really interests me as a glass reliability engineer are measurement systems that provide a statistically representative probability of failure,” he said. “The use case doesn’t really matter. Automotive glass, cellphone displays, architectural glass — you name it. If you’re not breaking glass — and not testing a representative number of samples to failure — you’re not doing your job as a reliability engineer.

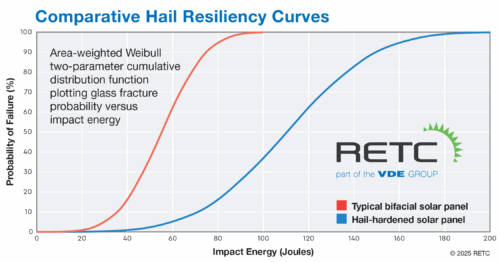

“If you gradually increase kinetic impact energy and test a meaningful number of samples to failure, you can generate Weibull distribution curves that plot the probability of glass failure on a product- or bill of materials-specific basis with low uncertainty,” Pilliod continued. “Now you can stack these Weibull curves and compare them. Do the curves overlap? If not, you can be reasonably certain that there is a statistical difference in resiliency.”

“If you gradually increase kinetic impact energy and test a meaningful number of samples to failure, you can generate Weibull distribution curves that plot the probability of glass failure on a product- or bill of materials-specific basis with low uncertainty,” Pilliod continued. “Now you can stack these Weibull curves and compare them. Do the curves overlap? If not, you can be reasonably certain that there is a statistical difference in resiliency.”

Early adopters of the test program represent a broad cross section of the solar manufacturing landscape, ranging from publicly traded module and tracker companies to venture-backed startups.

“We use the HRC test to qualify glass suppliers and innovative product designs,” said Chad Medcroft, SVP of global energy services at flat-ground-mounted solar company Erthos. “As the inventor of Earth Mount Solar, our focus is on module resilience rather than tracker operation. Because this approach challenges convention, we commission rigorous third-party testing to give customers, insurers and finance partners full confidence in our technology.”

News item from VDE